Heating cables manufacturer

TECHNITRACE is a company that specializes in the manufacturing of all type heating cables for electrical tracing. TECHNITRACE is also one of the few manufactures in the world with the expertise and technology enabling it to achieve in situ at its plant in Toucy (89 – Burgandy France) the manufacturing of self-regulating heating cables.

Technitrace heating cables manufacturer

Our product lines and our expertise of over 15 years’enable us to transform by extrusion a wide range of thermoplastics (plastic semi- conductors and techniques, PVC, TPR, SEBS, POLYURETHAN and fluoropolymers PVDF, ETFE, FEP, PFA, …).

We also braid (in copper and stainless steel), aluminum wrapping, resistive wires wrapping, personalized markings,….

A CERTIFIED COMPANY

The heating cables manufactured by TECHNITRACE meet the required standards of the French and European rules and regulations in vigor (CE). Quality checks are taken to insure (tracing of batch numbers, batch checks…)

The Company TECHNITRACE is quality certified ISO 9001:2008 and recognized and qualified ATEX (HAZARDOUS AREAS). All the necessary steps are taken throughout the long chain of production right up until the reception of our product by the customer.

TECHNITRACE has different automated test benches enabling permanent checks on the thermal characteristics concerning the self-regulating heating cables manufactured, but also to validate our expertise regarding our new semi-conductors and materiel in development.

A COMPANY THAT CONSTANTLY INNOVATES

TECHNITRACE constantly innovates in order to establish a system where they can constantly improve the characteristics for their manufactured products, accessories for more functional implementation, to be able to adapt to the needs of the market, customers, distributors concerning electrical tracing and surface heating.

- The NOVATRACE system

The NOVATRACE power management system associated with self regulating heating cables or constant wattage heating cables is the ideal system to

ensure constant temperature maintenance of pipe networks including numerous dead hydraulic arms or different hydraulic regimes.. See the complete technical sheet

- The MODULOTRACE concept

TECHITRACE has developped an innovating manufactury procedure (registred mark) that is an enormous help for the installators. See the video to understand the simplicity of this system.

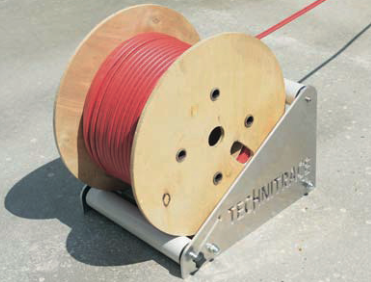

- Heating cable reel unwinder DER/NOVA

In order to facilitate your installations on-site, TECHNITRACE has designed and build a heating cable reel unwinder. Assembled and disassembled in just a few minutes, it adapts perfectly to all reels used by TECHNITRACE and its branches. As well as commercial reels with circular flanges below 80kg. See the complete technical sheet Der / Nova

A COMPANY AT THE SERVICE OF THEIR PARTNERS

TECHNITRACE provides its distributors, installators and partners a software system (3 parts – SNO) : based on the acquired entitlements, a complete and detailed proposal (pictures, price, delivery time, commercial terms…) can be made and sent to your customers with just a few clicks.

- The Selection (S) software allows you to perform the complete thermal calculation to maintain the temperature of an insulated pipe.

Automatic selection of the appropriate heating cable according to the selected technology (self regulating or constant wattage heating cable). Other additional technical data (power, current, thermal protection, …) are provided. - The list of material software (N) allows you to compose a complete list of all the material required in just a few clicks on pictures or from a ‘list box’. This list of material can be extended with your own accessories.

- The quotation software (O) allows you to make a quotation from a determined list of materials or an existing proposal. Quotations can be printed or saved/sent as pdf files.

A COMPANY AT THE SERVICE OF THEIR PARTNERS

Our extrusion product lines enable us to transform all the existing thermoplastics :

- Semi conductive and technical thermoplastics

- PVC LT/HT (85/105°C) – LD/HDPE (100°C) – PRC (115°C)

- PP (110°C) – EEA (125°) – EVA (125°C) – EMA (125°C)

- Elastomer thermoplastic TPR/TPE (125°) – EPDM (110°C)

- Fluoropolymers PVDF (150°C) – ETFE (150°C) – FEP (200°C) – PFA (260°C)